Proactive cost control is transforming how construction projects avoid overruns and maximize return, especially when powered by advanced construction project management software like Zepth. In this case study, we’ll follow a typical large commercial construction project—one with a USD 200 million baseline—to show how a disciplined, technology-driven approach to cost monitoring, risk management, and early intervention can realistically prevent losses worth tens of millions. Using smart construction management tools, this example shows not just savings, but how Zepth’s ecosystem, specifically Zepth Core, underwrites project success across every stage.

Project Profile: The Stakes in High-Value Construction

Picture a sprawling infrastructure project—say, a new metro station complex or corporate headquarters, with a budget hovering around the $200 million mark. Over 24 months, multiple subcontractors coordinate tasks across excavation, structure, MEP, and finishes. The sheer complexity means risks: contractors changing course midstream, scope creep, delayed procurement, and design changes threatening schedule and margin. In projects of this scale, even a modest 5% cost overrun means a painful $10 million in lost value. For many, these overruns are discovered only after they’ve accumulated, due to reactive processes and delayed reporting.

How did Zepth’s construction project tracking software change the outcome? By equipping teams with real-time data, process discipline, and AI-powered project management to catch risks as they emerge—not after the damage is done. This case study demonstrates that by proactively identifying and eliminating the root causes of overruns, the project team prevented a projected 7% overspend, delivering $14 million in avoided costs.

Shifting from Reactive to Proactive: Why Cost Control Must Change

Traditionally, many projects rely on periodic cost reviews—a “look back” after work is already completed. This reactive approach often means overruns surface once money is already out the door. A common scenario: change orders approved quickly without thorough analysis, historical trends overlooked, and siloed teams operating on outdated assumptions. The culture might echo, “We’ve always done it that way,” embedding inefficiency and waste.

Proactive cost control, by contrast, requires construction analytics and insights at every stage—breaking the project into granular spend categories, tracking leading indicators (like Cost Performance Index, CPI), and adjusting before issues snowball. Teams using Zepth’s enterprise platform segment their budgets, monitor real-time KPIs, and use AI risk management in construction to spot—and address—failures before they hit financials. A strong example: seeing signs of productivity lag in concrete works via daily field data on Zepth, the team reallocates resources and optimizes sequencing, heading off a $1.5 million overrun before it materializes. This future-facing mindset underpins digital transformation in the construction industry and directly impacts the bottom line.

Four Pillars of Proactive Cost Control (and How Zepth Delivers)

1. Robust Planning, Target Costing, and Smart Estimation

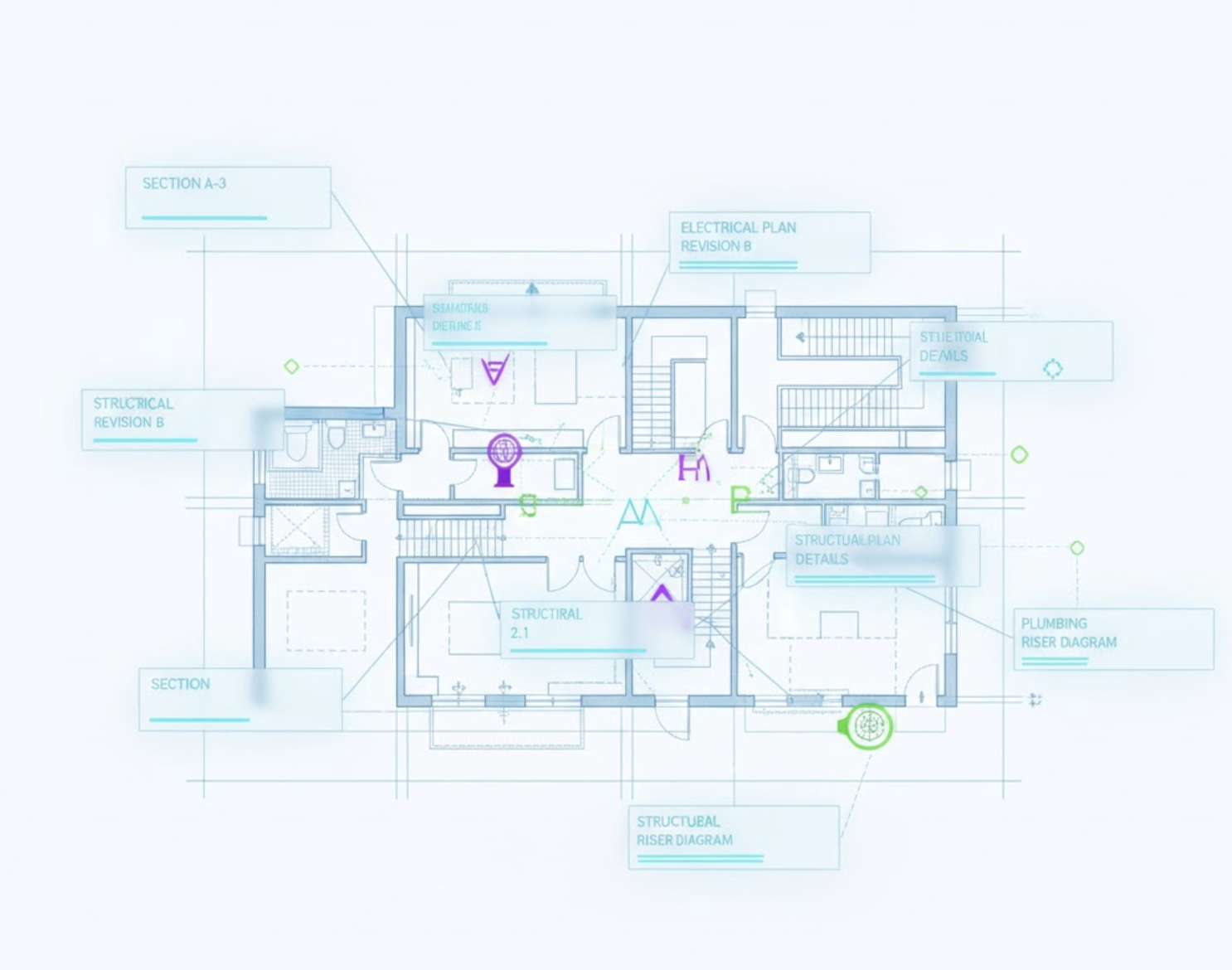

Preventing cost overruns starts long before ground is broken. Using Zepth’s construction lifecycle management software, estimators assemble a detailed work breakdown structure (WBS), benchmarking labor, equipment, and material costs against both internal and industry-wide historical data. With target costing, owners set a clear margin expectation, then designers and contractors iterate—optimizing elements until the plan meets financial objectives.

Lifecycle cost analyses enabled by Zepth encourage clients to choose options that reduce long-term claims and operating expenditure, even if they require slightly higher up-front investments—for example, specifying longer-life HVAC systems or energy-efficient glazing. Zepth’s centralized preconstruction planning module tracks every estimate, assumption, scenario, and revision, ensuring the baseline is robust and value-engineered options are fully considered. If you’re wondering, “What is the most effective way to reduce construction project overruns?”—the answer often lies in a combination of thorough up-front planning, cost benchmarking, and continuous scenario-testing from preconstruction through execution.

Key Zepth features for planning:

- Centralized repository for historical cost data

- Scenario-based budgeting tools for target-cost validation

- Integration with digital twins and BIM for design option analysis

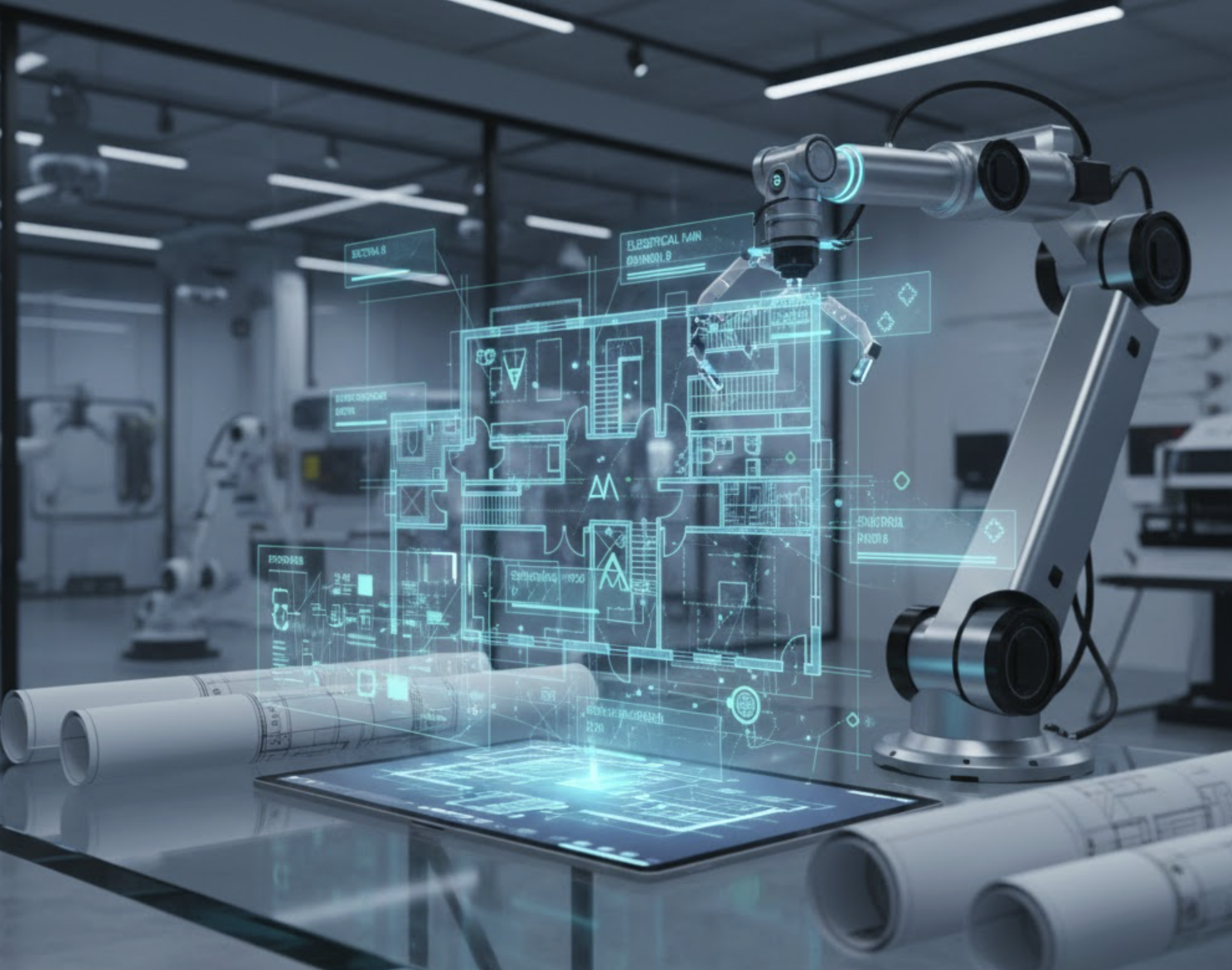

2. Value Engineering (VE) and Design Optimization

On a project of this scale, early application of structured value engineering through Zepth yields dramatic results. Teams evaluate alternative materials or designs—such as shifting from conventional to modular façades or optimizing slab thickness using AI construction automation—reducing capital costs without sacrificing quality. These proposals are logged, approved, and tracked in Zepth’s design coordination module, which ensures that realized savings are visible to all stakeholders.

BIM integration and constructability reviews flag design clashes before they result in costly on-site rework. If you ask, “How can value engineering improve construction cost performance?”—the answer is by using platforms like Zepth to systematically compare alternatives and fast-track approvals. On this case study project, VE and clash detection together realized $5 million in savings on envelope and MEP systems alone, while streamlining compliance and approvals through the collaborative common data environment for construction Zepth provides.

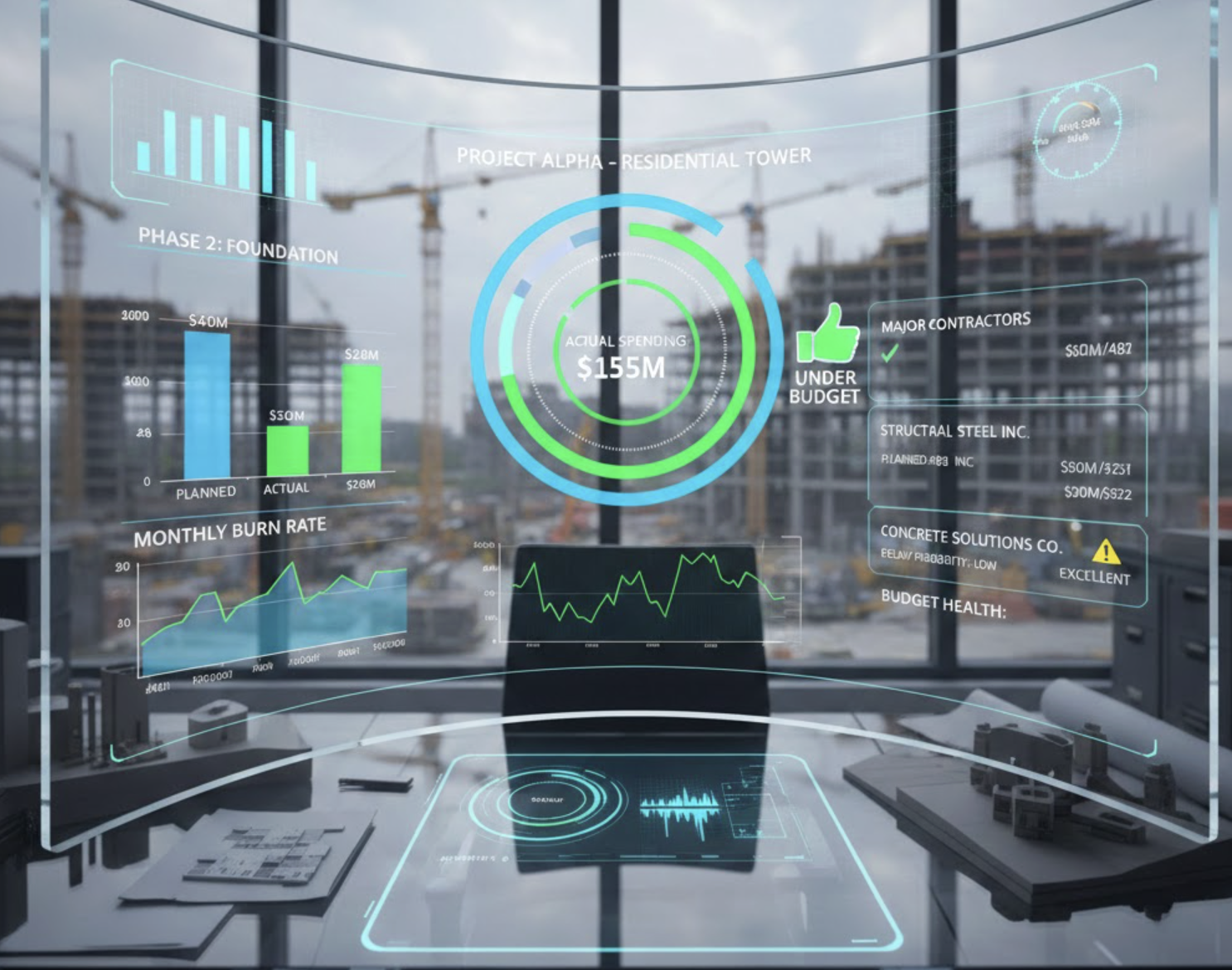

3. Real-Time Cost Tracking and Predictive KPIs

The move from historical reporting to real-time prediction is enabled by Zepth’s integrated cost dashboard: the very heartbeat of construction financial management tools. Here’s how it played out on our reference project: each week, automated dashboards updated key metrics—Cost Variance (CV), CPI, Schedule Performance Index (SPI), and Estimate at Completion (EAC). Teams received early alerts when trends suggested cost or schedule was slipping off course. With drill-downs by trade and phase, underperforming subcontractors were supported or replaced before impacts compounded across the schedule.

This proactive visibility is why advanced construction cost control software is rapidly becoming the industry norm. The real impact is best illustrated in field-level decisions: a drop in CPI triggered a prompt review of resource deployment in MEP installations, leading to crew realignment and sequence changes that brought performance back on track—averting a projected $1.3 million in additional costs. If you’re curious, “What KPIs should I monitor to proactively manage construction cost risk?”—essential metrics include CPI, CV, SPI, and EAC, all available via Zepth’s cost dashboards and project forecasting tools.

4. Daily Field Reporting and Active Issue Management

Zepth’s field data capture tools ensure the daily reality on site matches the goals set in the office. With mobile-first jobsite management tools, superintendents and subcontractors submit daily logs covering quantities installed, labor and equipment hours, safety incidents, and weather delays. These field reports flow directly into project analytics, supporting real-time cost and progress variance analysis.

Every RFI, design query, or site observation is time-stamped and linked to potential budget impact—streamlining response workflows and helping teams negotiate change orders early. The case study project saw over $2 million in potential claims and scope creep averted by quickly quantifying and closing out ‘gray area’ issues before they escalated. Need to clarify, “Why is daily reporting important for construction project control?” The answer: it provides the live data needed to spot deviations, manage risk, and implement corrective measures before costs spiral.

Beyond Overruns: Organizational and Strategic Impacts

Beyond single-project savings, Zepth’s cloud-based construction management platform helps organizations standardize processes, enforce HSE compliance, and develop a repeatable playbook for cost control across their portfolio. Data captured on one project enriches future estimates, improving forcecast reliability and reducing bid risk. The AI-driven orchestration—delivered through Zepth’s Anly and Edge platforms—extends to risk management, cost trending, document approvals, and beyond.

Centralizing all construction documents—designs, contracts, submittals, approvals—ensures everyone works from a single source of truth. Document registers, version-controlled submittals, and integrated authority approval tracking remove ambiguity and reduce the chance of disputes or claim-driven overruns. Insights & Analytics dashboards share real-time progress and risk data with both field and office teams, ensuring alignment and accountability.

Conclusion: Delivering Multimillion-Dollar Savings—A Repeatable Reality

This case study proves that with AI-driven construction management, rigorous process discipline, and comprehensive real-time data, proactive cost control isn’t just a best practice—it’s a source of competitive advantage that delivers direct value to owners and contractors. Zepth Core empowers teams to track every risk and cost driver in real time, making it possible to prevent the cumulative overruns that quietly erode margins across the built environment.

By embedding these principles and leveraging Zepth’s advanced construction tech innovation, organizations find savings measured not in thousands or hundreds of thousands—but in millions. That’s the promise, and the proven reality, of smart, cloud-based construction management for the next generation of project leaders.