Machine learning for predictive maintenance of construction equipment is rapidly transforming the way modern jobsite teams manage, monitor, and maintain their critical assets. As more construction companies turn to advanced construction project management software and AI-powered project management solutions, tools like Zepth Core are driving a shift from reactive repairs to proactive, data-driven strategies that dramatically cut downtime, costs, and extend equipment lifespan.

Understanding Predictive Maintenance and the Power of Machine Learning

Predictive maintenance (PdM) is a proactive, data-driven approach that anticipates asset failures by leveraging real-time sensor streams, historical records, and advanced analytics. Rather than waiting for machinery to break—often halting entire projects and inflating budgets—PdM leverages AI in construction to forecast failure points, so interventions occur just in time. This shift from time-based or purely reactive maintenance to condition-based and predictive methods is crucial in today’s competitive construction climate.

But why is machine learning at the heart of this revolution? Unlike basic manual methods or rule-based triggers, machine learning models can sift through massive troves of equipment data—vibration signatures, hydraulic pressure, temperature trends, and usage patterns. These AI tools for construction identify nuanced patterns and early warning signs of degradation that human experts, or even conventional analytics, often miss. The results speak for themselves: studies show AI-driven predictive maintenance can reduce equipment downtime by up to 50%, cut maintenance costs 18–30%, and boost asset lifecycle by as much as 25% across industries. These gains are even more pronounced in the construction sector, with its rugged conditions and mission-critical fleet needs.

This data-driven approach naturally leads to several questions. For instance, what is predictive maintenance in construction, and how does it differ from preventive or reactive methods? Predictive maintenance harnesses live and historical data to forecast the optimal timing for interventions, minimizing both unplanned breakdowns and unnecessary maintenance. By contrast, preventive maintenance sticks to fixed schedules regardless of real wear, while reactive maintenance only responds after a fault has occurred—usually with significant productivity and cost penalties.

Why Construction Equipment Is the Ideal Use Case

Heavy equipment fleets—excavators, loaders, cranes, generators—are the lifeblood of any large-scale construction project. These machines represent a huge capital investment, and a single unexpected failure can grind progress to a halt. With harsh worksite environments, variable loads, and widely dispersed assets, the traditional reactive approach to equipment service routinely leads to spiraling repair costs and costly project delays.

Modern predictive maintenance ecosystems in construction typically involve a blend of IoT sensors, robust data storage, and advanced analytics paired with smart jobsite management tools. Sensors continuously gather data on engine vibrations, hydraulic systems, fuel consumption, oil quality, temperature, load cycles, and more—feeding this real-time stream to centralized construction analytics and insights platforms like Zepth Core. Telematics gateways send all this information straight to the cloud, where AI construction automation algorithms process it for actionable insights.

- Remote Monitoring: Real-time insights enable fleet monitoring and failure prediction from any location.

- Data Integration: Sync sensor data with maintenance logs, operator reports, and OEM fault codes.

- ML-Driven Risk Scoring: Predict potential faults and remaining useful life for each asset.

- Automated Actions: Trigger maintenance requests, schedule crews, and order parts directly from the platform.

- Continuous Feedback: Models learn and improve as more failures and repairs are documented.

This sophisticated ecosystem not only optimizes maintenance but strengthens safety management in construction—as early detection of faults helps prevent accidents due to mechanical failure. It also empowers better project cost control, supporting initiatives in construction financial management and risk reduction.

People new to the topic sometimes wonder: how does predictive maintenance use real-time construction project data to make equipment management more efficient? The answer lies in the ability of machine learning to combine readings from disparate sensors with operational context (e.g., duty cycles, loads, site environment), maintenance logs, and even project schedules—enabling more precise predictions and smarter resource allocation.

How Machine Learning Powers Predictive Maintenance

Machine learning models are the engine behind PdM’s reliability and accuracy. In construction, these models come in many flavors:

Supervised learning methods use historical data labeled with failure events to predict breakdowns or estimate Remaining Useful Life (RUL). Models such as regression, neural networks, and survival analysis excel in this arena, letting teams know how much longer a particular excavator or generator is likely to perform reliably.

Unsupervised learning techniques (such as clustering or anomaly detection) are invaluable when labeled failure data is sparse—a common scenario for rarely-failing, expensive assets. These models can flag unusual changes in vibration, temperatures, or hydraulic pressure before a catastrophic failure occurs.

Semi-supervised and transfer learning approaches allow for learning from small labeled datasets and leveraging patterns across similar machine types, while reinforcement learning dynamically balances maintenance scheduling against downtime and cost risks.

Typical predictive maintenance workflows in construction include:

- Data ingestion: Pull sensor feeds, operator comments, and OEM codes into the common data environment for construction.

- Feature engineering: Compute rolling averages, spikes, and variance in key indicators; contextualize by jobsite and usage patterns.

- Model training and deployment: Fit models to predict failures, classify risky equipment, and estimate RUL, then deploy to score live data for alerts.

- Integration with operations: Push maintenance recommendations or work orders to fleet and project management systems like Zepth Core.

- Continuous improvement: Update models as more operational and maintenance data flows in, improving predictive accuracy with scale.

Construction professionals frequently ask: why is AI-driven construction management becoming essential to equipment maintenance? It’s because AI allows teams to manage risk dynamically and allocate resources with surgical precision—something traditional calendar-based or reactive models cannot do. Machine learning not only predicts failures but also optimizes the entire maintenance lifecycle for reduced cost and minimal project disruption.

Zepth Core: The Next-Level Platform for AI-Driven Predictive Maintenance

Zepth Core stands at the forefront of this digital transformation, offering a comprehensive construction project tracking software suite that integrates predictive maintenance, asset management, document control, and risk analytics all under one roof. At the heart of Zepth’s platform lies seamless connectivity of jobsite information, analytics, and actionable insights—empowering construction teams to act fast, reduce costs, and put safety first.

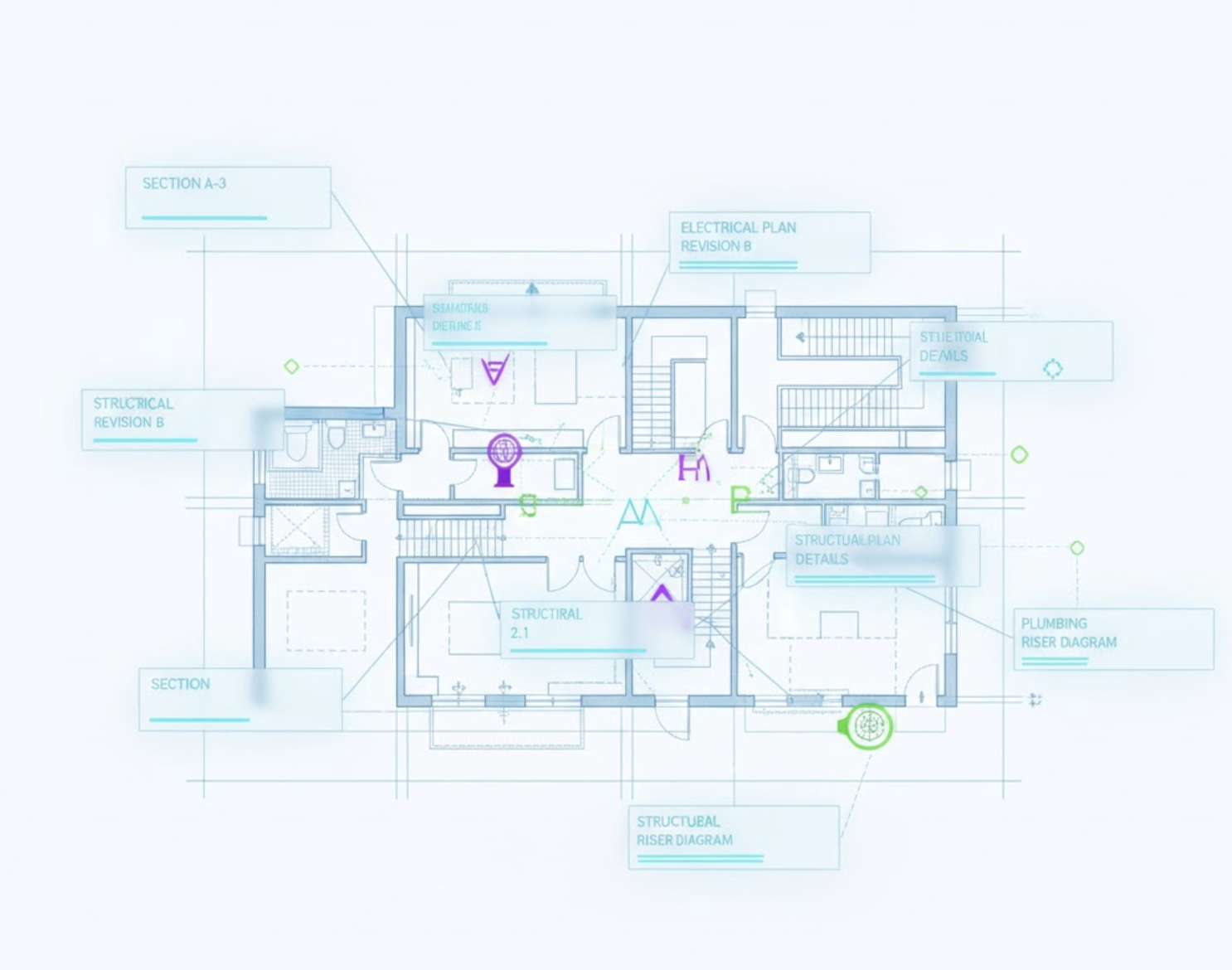

Zepth Core’s Jobsite Management Suite is built for modern equipment maintenance workflows. With real-time incident reporting, daily progress and condition logs, visual dashboards from Zepth360, and customizable snag lists, site teams capture critical operational context for each piece of machinery. The risk management module—covering risk registers, mitigation plans, and AI-powered risk reporting—integrates with maintenance analytics to better anticipate and resolve emerging issues, strengthening overall construction risk management.

The document management stack simplifies collaboration on manuals, inspection sheets, maintenance logs, and compliance documentation, all in a secure audit trail. By centralizing communications—RFIs, submittals, site observations—Zepth ensures no detail is missed when planning, executing, or following up on predictive maintenance work orders. The project financials module links maintenance costs and asset lifecycles directly to project budgets, supporting smarter investment and purchasing decisions.

Further elevating the experience is Zepth’s AI-powered analytics and insights, which enable thresholds, risk scoring, and predictive alerts to be tuned in real-time. The platform’s common data environment for construction ensures that each data point, from fleet telematics to crew feedback, is accessible, contextualized, and actionable. This accelerates maintenance response and minimizes paperwork. As a smart construction management tool, Zepth automates many formerly manual steps—simplifying everything from compliance checks to cost forecasting and asset reliability analytics.

Best Practices, Future Trends, and Sustainable Impact

To unlock maximum value from AI-driven predictive maintenance, construction firms should strive for several key practices:

- Deploy a comprehensive sensor suite on all major assets.

- Integrate telematics and operator input for richer, more complete datasets.

- Adopt a cloud-based construction management platform that supports real-time data processing and multi-site coordination.

- Centralize equipment health, maintenance, and cost data in a single construction lifecycle management software environment for full visibility.

- Establish closed feedback loops: continuously retrain machine learning models on operational and failure outcomes.

- Prioritize crew training, change management, and cyber-security as data flows increase.

Looking ahead, the fusion of BIM (Building Information Modeling) integration, digital twins in construction, and next-gen AI promise even more precise simulation and prediction of equipment health within full project context. This will enable project teams to anticipate bottlenecks, optimize resource scheduling, and minimize environmental impact, supporting goals in sustainable construction management.

Many construction leaders are asking: how can we ensure predictive maintenance contributes to both operational efficiency and sustainability? The answer lies in extended equipment life, fewer emergency repairs (and associated emissions), and optimized parts usage—all enabled by a robust AI construction platform like Zepth Core. This digital transformation isn’t just about reducing costs or mitigating risk; it’s about building safer, smarter, and more sustainable job sites for the future.

In summary, adopting machine learning-enabled predictive maintenance is a strategic move for construction companies intent on driving efficiency, profitability, and resilience. Platforms like Zepth Core unify the workflows, data, and intelligent insights necessary to make this powerful approach practical, actionable, and transformative across every phase of construction equipment management.