Construction project management software is experiencing a dramatic evolution with the adoption of AI-enabled jobsite monitoring. As digital transformation accelerates across the built world, construction companies are leveraging AI tools for construction safety, productivity, and compliance like never before. These platforms revolutionize the traditional approach—where jobsite managers relied on post-facto incident reports and manual safety rounds—by offering real-time risk awareness, predictive analytics, and operational control. The impact? Safer sites, smarter resource allocation, and unmatched transparency across the construction lifecycle.

What Drives AI-Enabled Jobsite Monitoring?

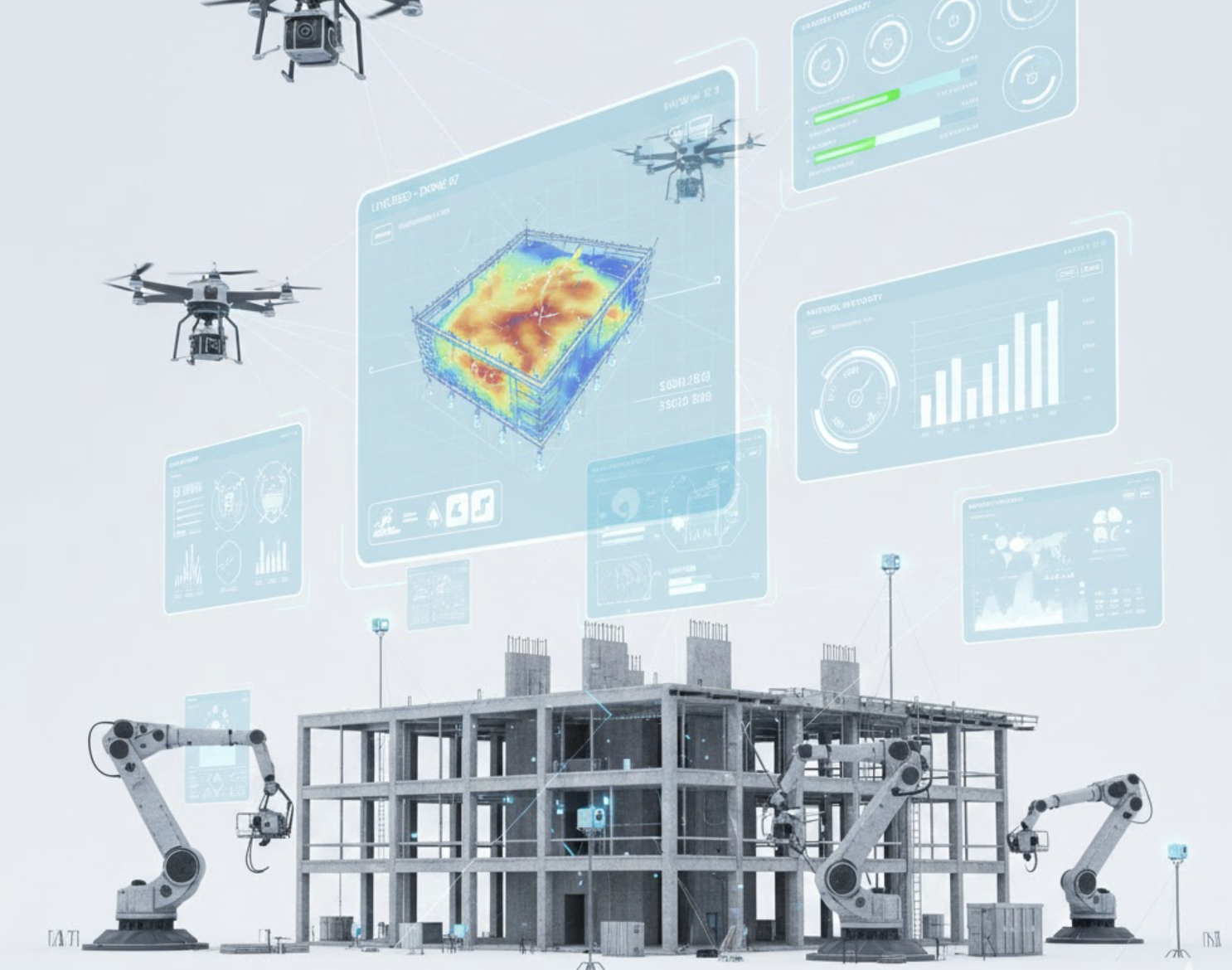

AI-powered project management technologies combine intelligent cameras, IoT sensors, and cloud analytics to deliver 24/7 visibility on site conditions and worker behavior. The architecture behind these jobsite management tools involves hardware (high-resolution cameras, rugged sensors), software (machine learning for image and behavior analysis), and robust cloud platforms for storing data and generating construction analytics and insights. Supervisors access these insights through web dashboards or mobile interfaces, enabling them to make faster, better-informed decisions from anywhere in the world.

Comprehensive camera placement—encompassing fixed zones, vehicle-mounted dash cams, and wearable 360-degree cameras—ensures complete coverage. This setup enables tracking of moving machinery, monitoring high-risk areas, and documenting worker activities from every angle. With this multi-layered system in place, firms can achieve effective coverage for both static hazards and dynamic, unpredictable site environments.

How Does AI Improve Construction Site Safety?

The most profound benefit of AI-enabled monitoring is real-time hazard detection. Soon after deployment, construction firms observe AI identifying PPE non-compliance (such as missing hardhats, gloves, or vests), detecting when workers enter restricted zones, and flagging unsafe or unauthorized behavior around equipment. This isn’t just about catching mistakes—it’s about preventing accidents before they occur. For example, the system can recognize when someone steps behind a reversing vehicle or when scaffolding has been left unsecured, alerting supervisors instantly for intervention.

Beyond immediate detection, these platforms continuously track worker behavior for safety compliance. The automation reduces manual rounds and provides a permanent, unbiased record of compliance adherence—an invaluable resource for incident investigation and regulatory documentation. AI-powered jobsite management tools help safety managers move from reactive responses to proactive prevention. Do you ever wonder, How can construction sites quickly detect safety violations? The answer now lies in these smart platforms’ instant analysis of video and sensor data, making the jobsite safer while minimizing human oversight fatigue.

- PPE detection with real-time alerts

- Zone entry detection for unauthorized access

- Driver behavior monitoring (speed, distractions, harsh maneuvers)

- Edge AI for on-device processing—minimal delay and bandwidth use

- Cloud access for anytime, anywhere oversight

- Automatic event tagging and searchable incident logs

- Integration capabilities with construction document management and EHS systems

Perhaps you’re considering, What tools help construction companies comply with safety regulations? Modern AI-enabled jobsite monitoring addresses this need directly by providing continual evidence for OSHA and regulatory compliance, automating what once required exhaustive manual reporting, and simplifying risk audits and investigations with comprehensive digital logs.

Driving Productivity and Operational Excellence

AI in construction goes beyond safety: productive sites are smart sites. AI-powered construction management tools monitor equipment use, detect idle time, and analyze crew deployment—identifying bottlenecks and inefficiencies instantly. Managers visualize data via real-time dashboards, allowing for precise resource allocation and timeline adjustments on the fly. Construction project tracking software with integrated AI analytics turns complex site activity into actionable business intelligence.

For instance, when AI analytics highlight underutilized equipment or workflow bottlenecks, project leaders can shift machinery or modify crew schedules to optimize productivity—reducing unnecessary downtime and driving cost savings. When considering How can technology minimize project delays in construction? the answer is in these platforms’ 24/7 monitoring capabilities. Theft and vandalism, persistent risks in construction, are drastically reduced thanks to continuous remote video verification and rapid response to suspicious activity. This ensures valuable equipment stays secure, schedules are maintained, and unforeseen costs are avoided.

AI-Driven Risk Management and Financial Impact

Risk management in construction has long relied on traditional reviews and manual logs. AI-powered risk management in construction, however, eliminates guesswork by detecting, logging, and predicting hazards based on live and historical site data. Risk registers, mitigation plans, and risk reporting modules—such as found in Zepth Core—work together to provide one digital environment for classifying risks, assigning action items, and monitoring mitigation progress. Incorporating AI tools for construction risk management means organizations move ahead of incidents, instead of just responding.

The ROI for AI-enabled jobsite monitoring is tangible. Lower incident rates decrease workers’ compensation claims. Stronger safety records lead to better insurance premiums and improved reputational standing—particularly crucial when bidding for large-scale public or enterprise projects where documented compliance is essential. Besides, continuous jobsite monitoring reduces project delays and asset loss, both critical contributors to the overall financial health and forecasting accuracy of construction firms.

What Features Set Leading Platforms Apart?

The features prioritized in a modern AI construction platform include:

- Edge AI processing for real-time hazard recognition

- Cloud integration—enabling access from any device, anywhere

- PPE and zone entry detection, with configurable alert thresholds

- Driver and equipment behavior analytics

- Rugged, durable hardware for tough jobsite conditions

- Seamless integration with project management and EHS systems

For example, platforms such as Zepth Core provide unified modules for jobsite management, inspections, snag lists, HSE compliance, non-conformance, incident reporting, and real-time daily/progress reports. Zepth’s Zepth360 module enables immersive visual reporting, letting teams capture and share updates using photos, videos, and even 360-degree views, all linked to the digital project model or site locations. Zepth’s document management ecosystem—centralizing documents, RFIs, submittals, and authority approvals—supports a true common data environment for construction, where every stakeholder works from the same set of real-time project data.

Wondering, What is the benefit of digital twins in construction? Platforms integrating digital twins and BIM models with AI monitoring, such as Zepth’s ecosystem, create a living model of the jobsite that updates in sync with real-world conditions—empowering in-depth project tracking, construction lifecycle management, and superior risk forecasting.

Future Directions: Smart Construction and Zepth’s Advantage

The construction tech innovation wave shows no sign of slowing. AI construction automation, the convergence of IoT and smart construction management tools, and cloud-based construction management are rapidly becoming industry standards. These technologies not only boost safety, but also profoundly improve scheduling, cost control, and project documentation.

Zepth Core is purpose-built for enterprise construction project management, providing an ecosystem where AI, analytics, and document control are seamlessly unified. Modules for risk registers, mitigation plans, project cost control, financial tracking, and advanced construction forecasting tools align fully with the needs of builders managing multi-site operations, heavy civil projects, and high-risk, high-value equipment fleets. By enabling integration across Zepth Edge (for financial and asset management), Zepth Flow (procurement management), and Zepth Anly (AI orchestration and automation), organizations gain a holistic solution for digital transformation—creating sustainable, compliant, and efficient jobsites.

In an era marked by labor shortages, increased regulatory demands, and the call for sustainable construction management, AI-powered jobsite monitoring stands out as a vital driver of success. Platforms like Zepth are positioned at the forefront—turning real-time site data into business value, minimizing risk, and giving forward-thinking firms the edge in a competitive marketplace.